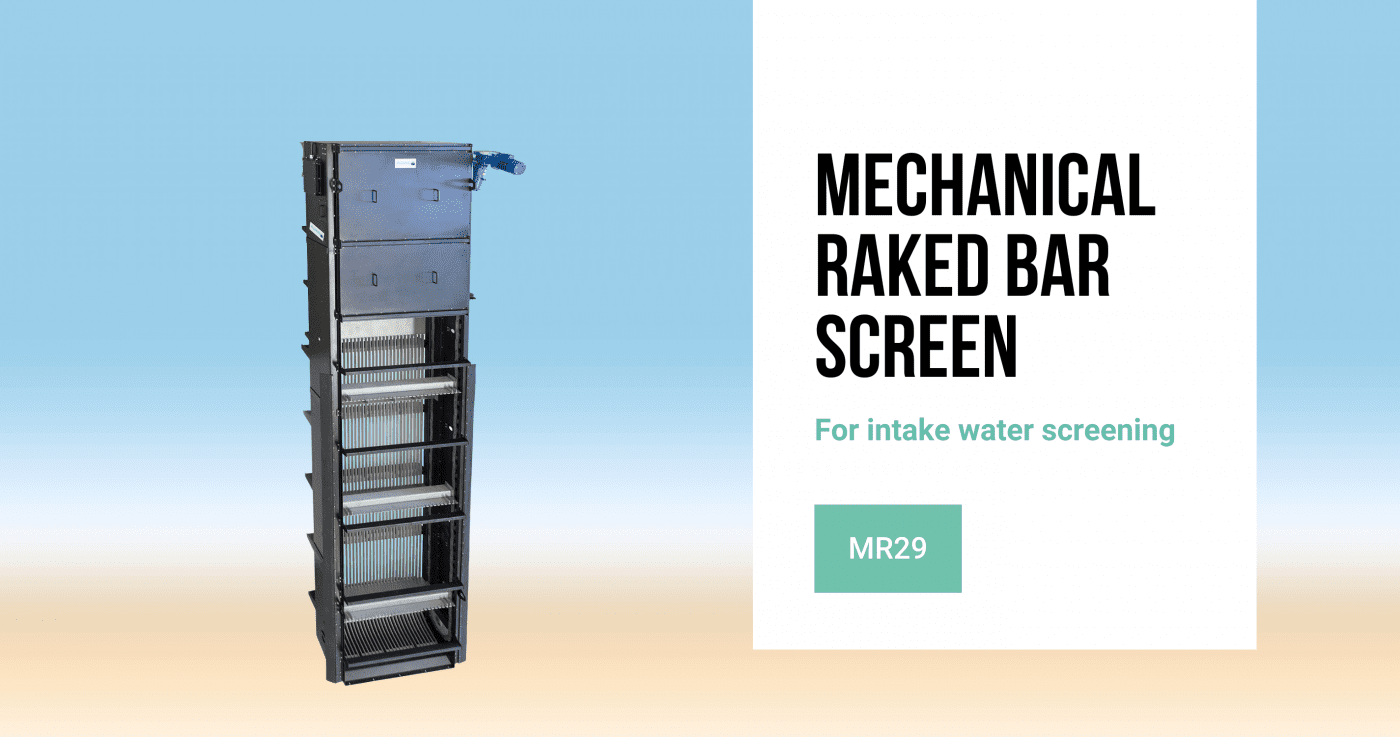

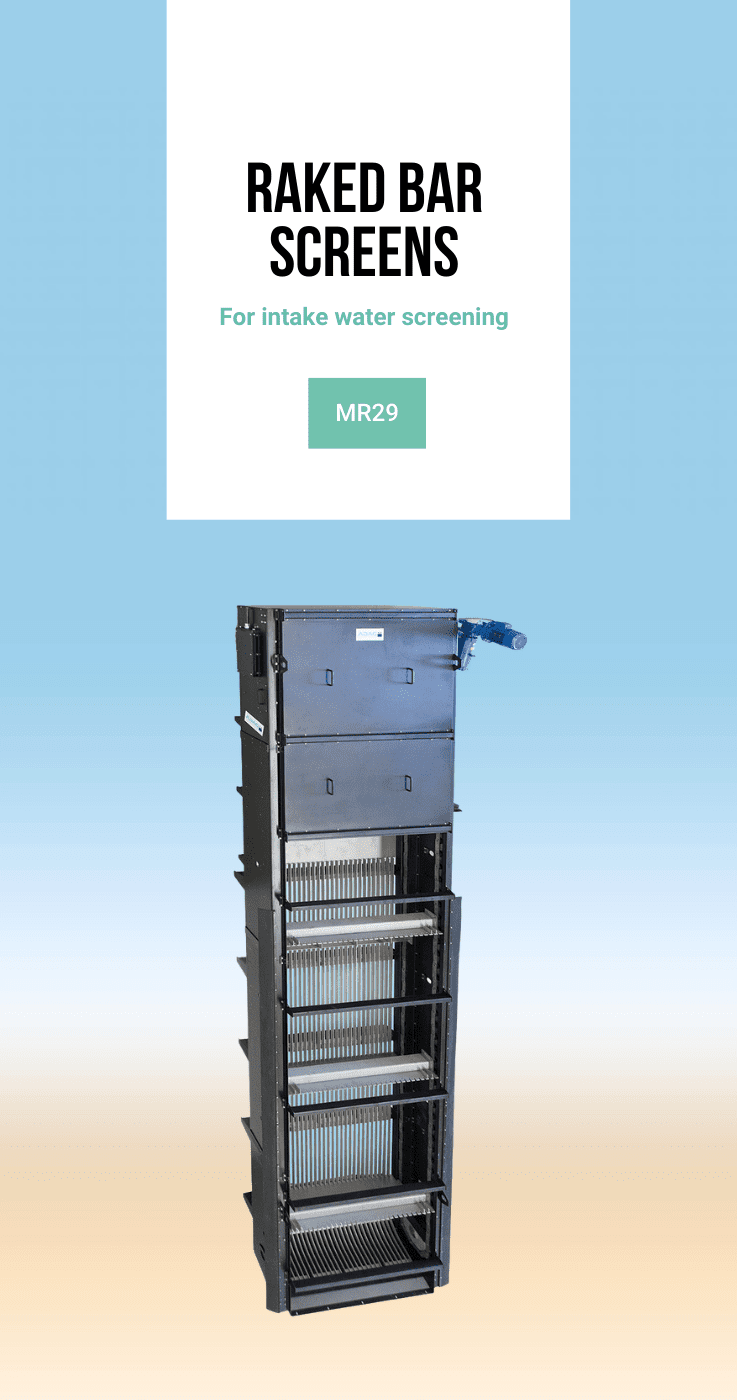

DESCRIPTION

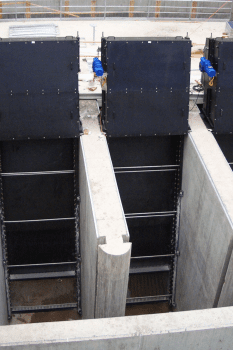

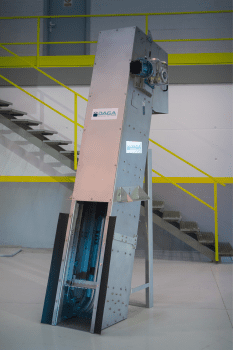

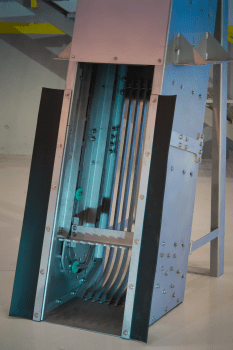

Vertical and mechanically raked bar screen constructed out of high quality stainless steel bars for intake screening and refuse removal. The solids captured on the bar screen are removed on the top of the equipment by cleaning rakes which are moved by two lateral chains. The solids are then expelled out the shoot point.

The unit housing, the translation chains and the cleaning system are designed to ensure long-term trouble-free operation. Fitted lateral sealing bands and adjustable anchoring are also provided to suit channel requirements. The amount of rakes will depend on the screening height and the operation conditions (flow, screening discharge capacity, particles sizes, density of residues to be withdrawn, etc.)

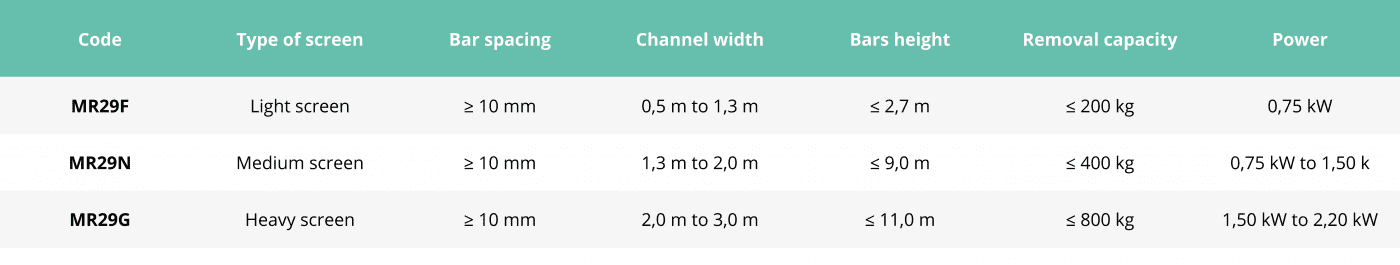

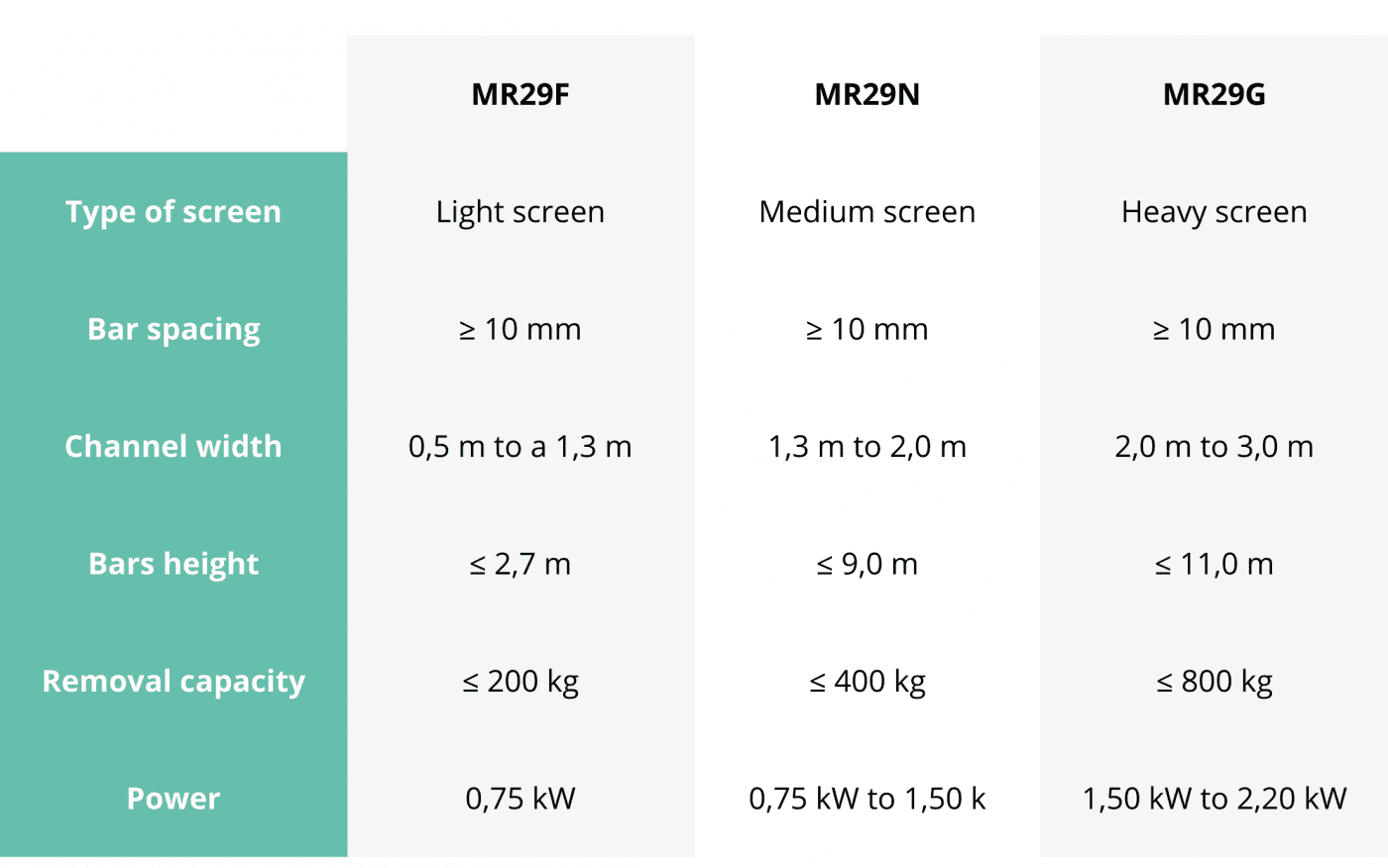

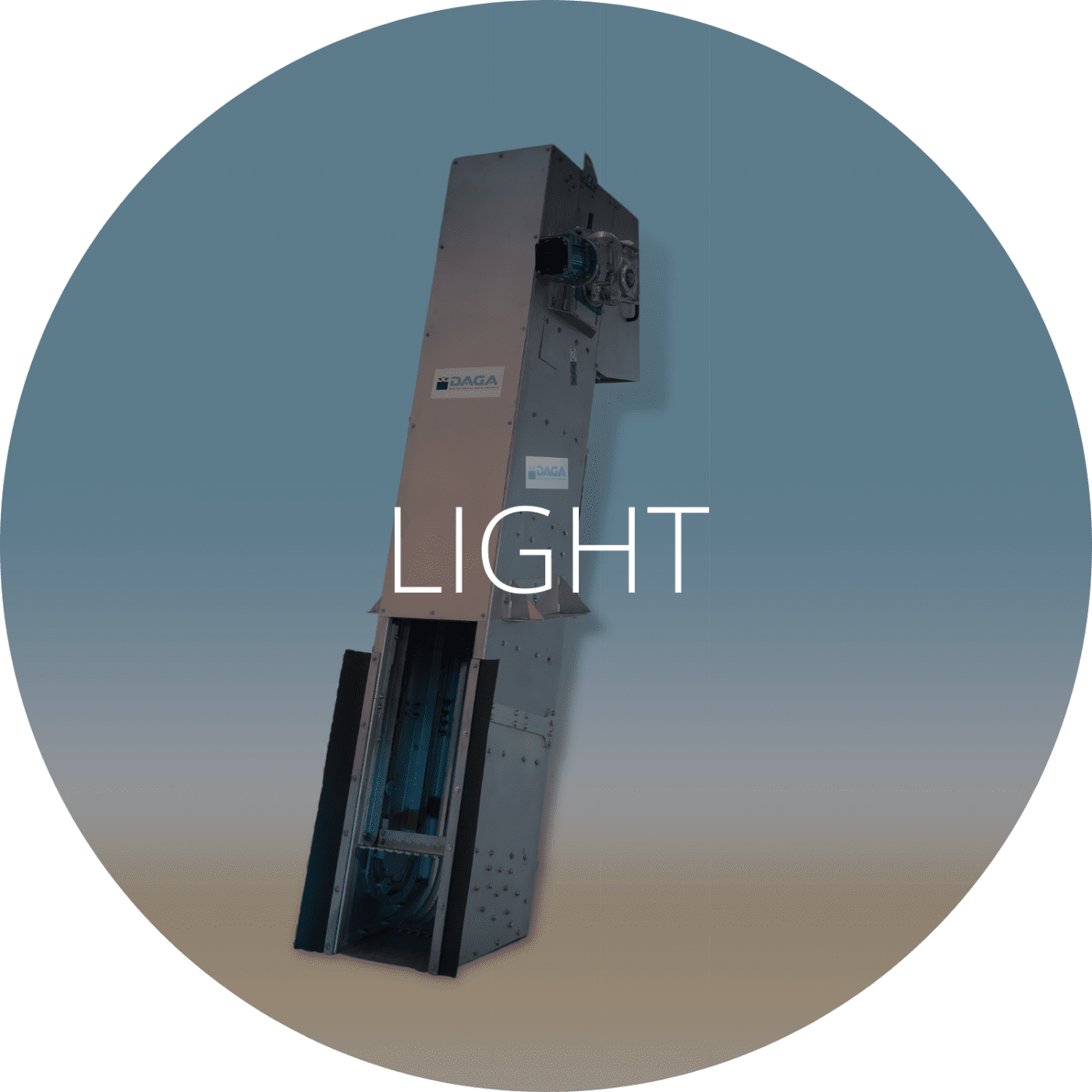

This model is useful for channels up to 1.3m wide, a water height of 2.7m and a lifting load of 200Kg.

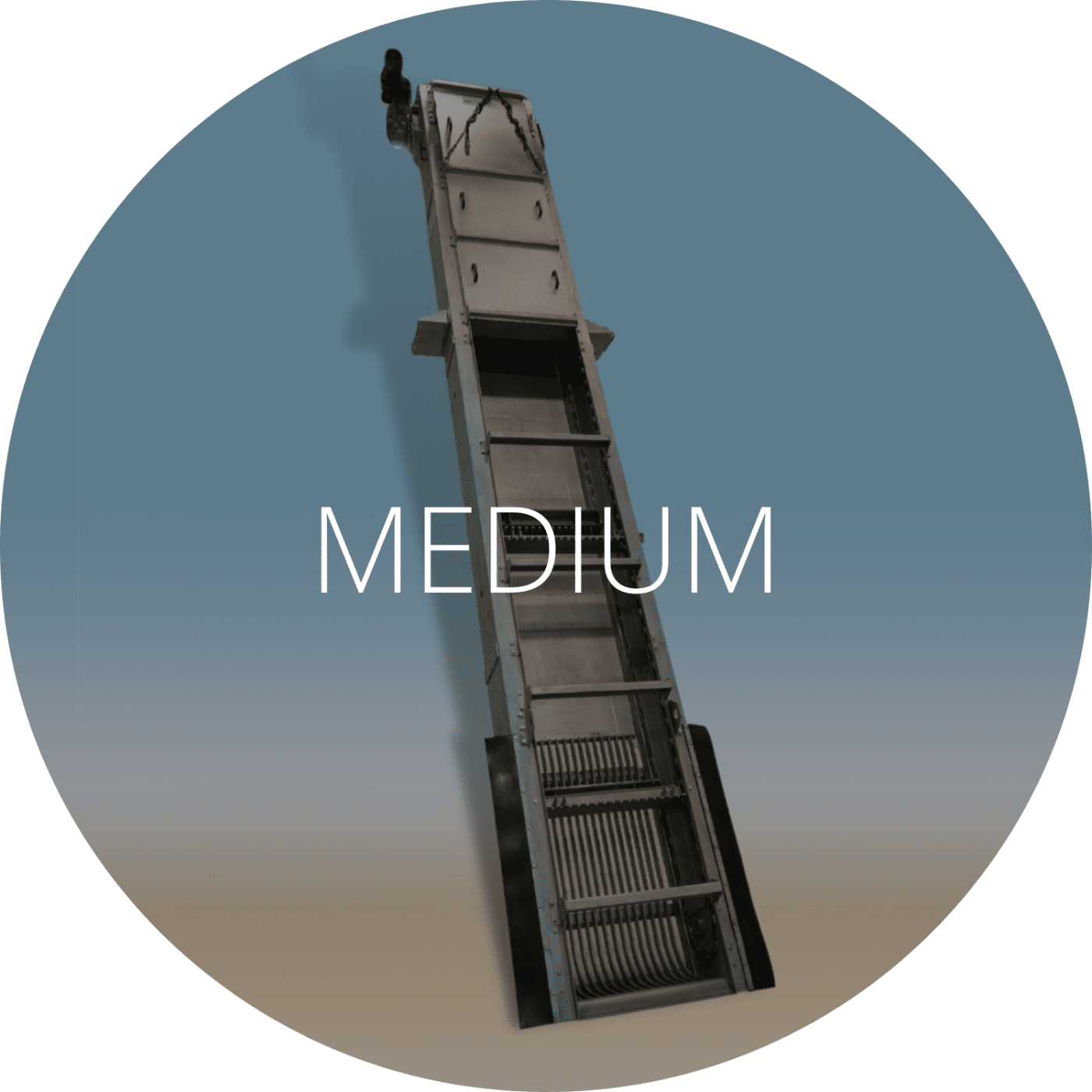

This model is useful for channels up to 2m wide, a water height of 9m and with a lifting load of 400Kg.

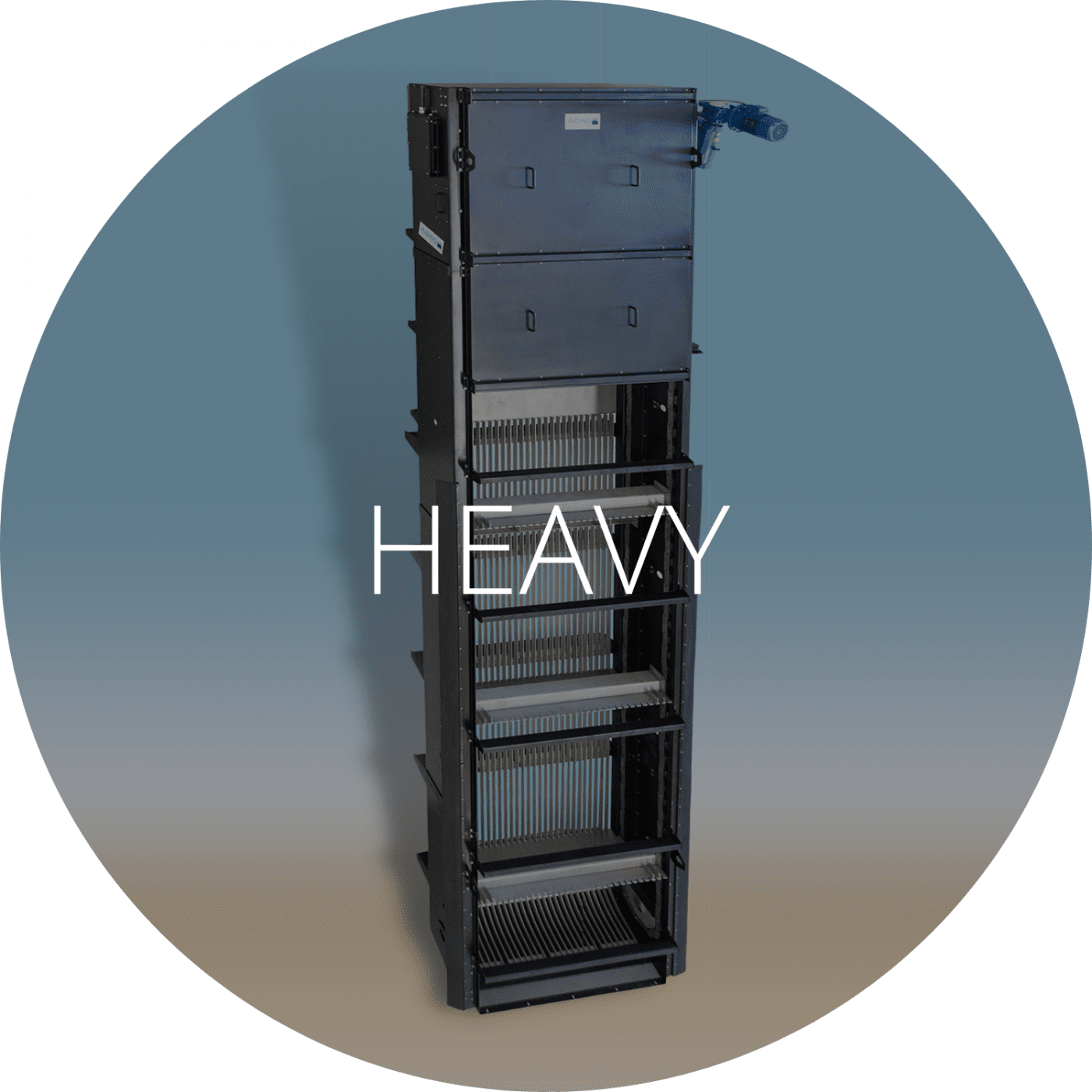

This model G is useful for channels up to 3m wide, a water height of 11m and with a lifting load of 800Kg.

FEATURES

-

Effective solids separation and high screening discharge capacity.

-

Applications for a wide range of particle sizes of refuse.

-

Delivery of pre-engineered systems to be easily assembled by local labour.

- Use for intake screening for irrigation and the pre- treatment process of water treatment facilities.

APPLICATION

Vertical & mechanically raked bar screens are used for water screening and water treatment, removing solid refuse and improving downstream pumping and pipeline efficiency.

In the case of wastewater treatment plants, the raked bar screens are part of the pre-treatment process phase.

In the case of irrigation works, the raked bar screens provide an effective solid separation of intake water: solids and debris are captured and elevated to the discharge point while filtered water continues downstream.